Gooda CNC Pneumatic Clamping Chamfering Machine Pneumatic and Electromagnetic Worktable with Protection Hood with Safety Lock (DJX3-1200-700S)

Basic Info

| Model NO. | DJX3-1200-700S |

| After-sales Service | Machine Whole Usage Period |

| Warranty | One Year |

| Control Axis Number | 3 |

| Chamfer Parameters | C1, C1.5, C2, C2.5, C3, C3.5, C4 |

| Certificate | CE/ ISO 9001/SGS |

| Workpiece T*W*L mm | 25-300*100-700*100-1200mm |

| Dimensionstmm | 3370*1750*2000mm |

| Machine Weight | 3900kg |

| Spindle Speed(Infinitely Variable Speeds | 2800rmp |

| Spindle Powertkw | 0.75kw |

| Cutting Diametertmm | 90mm |

| Pneumatic Float Magnetic Chuck System | 700*1350 |

| Space | 4X2.5m2 |

| X/Z Max Cutting Speed | 4000mm/Min |

| X/Z Max Feed Speed M/Min | 10000mm/Min |

| X/Y/Z Motor Power | 1.0/1.5/1.0kw |

| Surface Roughness | Ra≤1.6 |

| Transport Package | Steel Box/Pallet Package |

| Specification | 3.5x2.5 |

| Trademark | Gooda brand |

| Origin | Guangdong, China |

| HS Code | 8458190000 |

| Production Capacity | 500sets/Year |

Product Description

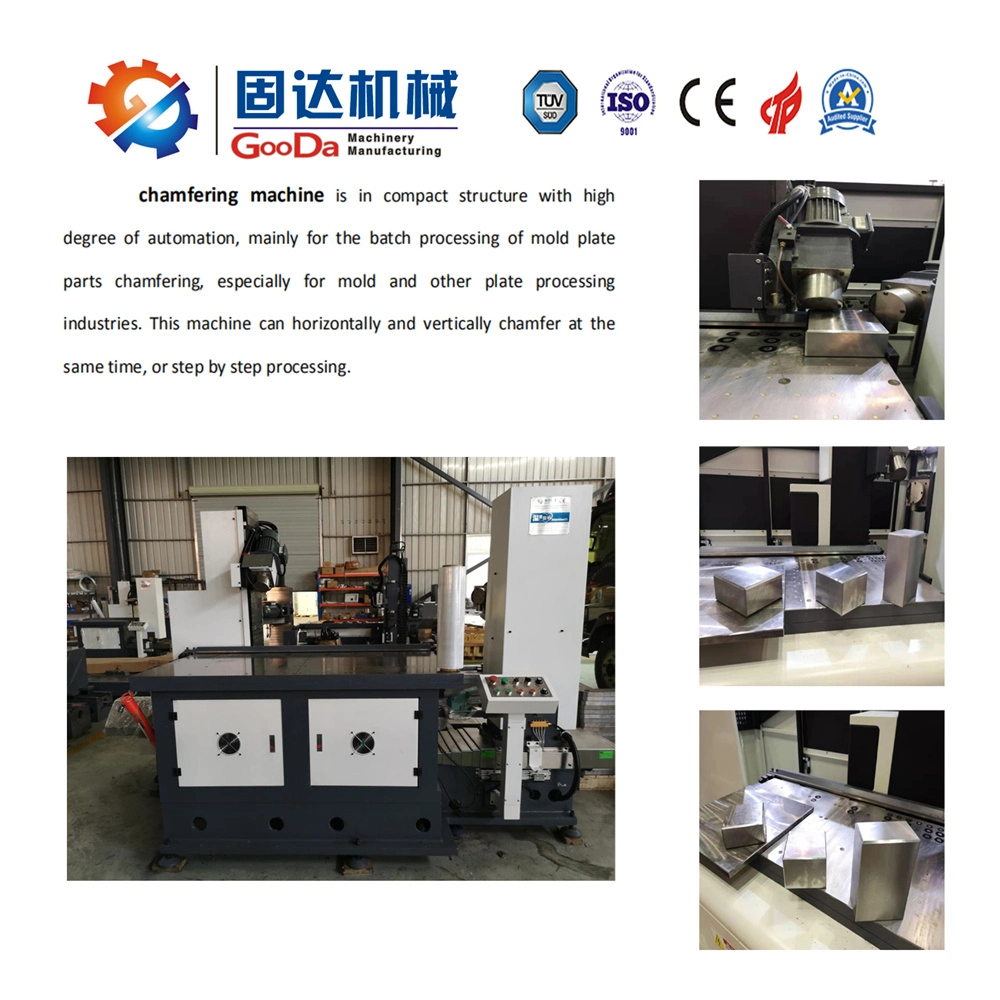

Trinity Ganged Chamfering Machine machine(DJX3 1000-700S)

The Chamfering machine is optionally fitted with pneumatic clamping devices enabling the workpiece to be turned quickly. Workpiece with a maximum length of 1200 mm, a maximum thickness of 250 mm and a maximum width of 1200 mm can be milled as standard. Optionally, chamfering C1,C2,C3,C4 are available.NC system once-setting for automatic measurement, Pneumatic Float Magnetic chuck worktable, three cutter ganged, three edges at one time, triple faster, no need to turn-over the workpiece, Multiple Chamfering C1, C2, C3, C4 Easy to change. Smooth line Chamfering, NC-controlled positioning of the axes.

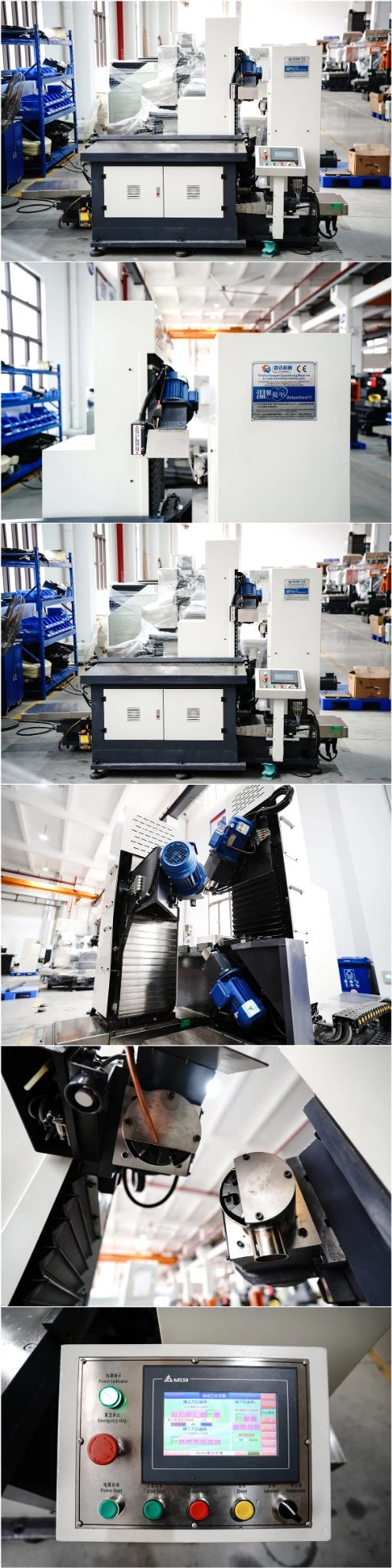

Detailed Photos

Manufacturing capacity

CNC Trinity chamfering machine DJx3-1000-700S

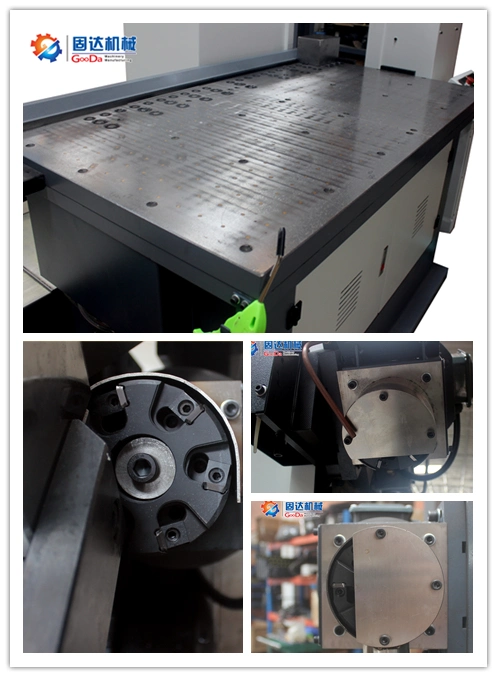

Configuration:* Three Cutters* Pneumatic clamping* CNC-controlled positioning of the axes* Protection hood with safety lockMain Parts:NC system: TaiwanServo motor: CTBAC contactor: Taiwan TECOIntermediate relay: Japan OMRONBearing: Germany FAGWorktable ball screw: Taiwan

Specification

Specifications of CNC Trinity Ganged Chamfering Machine(DJX3 1000-700S )

DJX3 1000-700S CNC chamfering machine-mold base edges milling machine-steel plate edges milling machine-manifold block edges milling machine

Main Function:

CNC system once setting and automatic guides where work-piece loading place, automatic measurement, four- sides process, which can reduce working strength of operator and increase Productivity, maintain high accuracy for dimension, squareness and parallelism.

Specifications of Trinity Ganged Chamfering Machine machine(DJX3 1000-700S ) | ||

| Items | Name | Specification |

| GooDa Trinity Ganged Chamfering Machine machine(DJX3 1000-700S) | DJX3 1000-700S | |

| Cutting capacity | Control axis number | 3 |

| Cutting capacity mm | C4 | |

| Workpiece T*W*L mm | 25-300*100-700*100-1200 | |

| Worktable | Dimensions mm | 700*1350 |

| Max loading weight | 3900 | |

| Spindle | Spindle speed(Infinitely variable speeds) | 2800 |

| Spindle power KW | 0.75 | |

| Cutting diameter mm | 90 | |

| X axis | X/Z axis motor power | 1.0 |

| X/Z Max feed speed m/min: | 10.0/1.0 | |

| Z axis | X/Z Max cutting speed | 4.0/1.0 |

| Tank capacity | Pneumatic Float Magnetic chuck System | 800*1400 |

| Lubrication injection ports | 5 | |

| Power | Power | AC380V/220 10KVA |

| Net weight | Machine net weight KG | 3900 |

Main part of CNC Trinity Ganged Chamfering Machine(DJX3 1000-700S )

| Sort | Name | Quantity | Origin | Remark |

| Machinery | Screw | 2 | Taiwan | steady transmission,High accuracy, wear-proof |

guide rail | 2 | High accuracy linear guide rail | Good bearing, wear resistant | |

| Spindle | 3 | Taiwan | Low noise, high strength, Taiwan famous brand | |

| Flexible stainless steel plate shield of worktable | 2 | Domestic | High strength,Strong durability, dust-proof, Protect the guide rail and ball screw. | |

| Base casting | 1 | HT300 | Good stability, excellent wear-ability | |

| Lubrication injection ports | 5 | Domestic | Electronic-Auto-lubrication, Quantitative Lub oil supply to the each part | |

| Bearing | 6 | Japan NSK | World famous brand,High accuracy, High quality | |

| Electrical appliances | NC system | 1 | Taiwan | High accuracy |

| Motor | 2+3 | Delta | Multitronic, Meet the requirements of different processing speed | |

| Magnetic chuck System | 1 | Taiwan | Taiwan famous brand,High accuracy | |

| AC contactor | Taiwan | Famous brand, steady property | ||

| Relay | Japan OMRON |

Certifications

Packaging & Shipping

Packing and shipping

To be packed in fumigation wooden case or in steel box,suitable for long distance ocean transportation,well protected against moisture and shocks,pressure wetness.

Company Profile

FAQ

FAQ:1. What is your minimum order quantity and warranty? MOQ is one set, and warranty is one year.2.What CNC system do you use? FANUC, SIEMENS, MISTSUBISHI etc. It depends on your choice.3.When is the delivery time? Conventional Machines,We will delivery then within 30-45 working days after received your deposit,if some special machines will be some longer.we will give you the answer accordingly.4. What is the package of the machines? Packing: PE bag cover inside+ Plywood box + Steel beam frame.5.How can I choose the most suitable machines ? Please let us know your machining demand or machine size ,we can choose the best model for you , or you can choose the exact model by yourself. You can also send us the products drawing ,we will choose the most suitable machines for you .6. What is your trade terms? FOB, CFR,CIF or others terms are all acceptable.7. What is your payment terms ? Payment Terms : T/T 30% advance , 70% before shipment.

The benefits of GOODA maintenance contract (After sales 3 years):

- Basic requirement in a certified QS system

- Guarantee for the accuracy of the measuring and test results

- Calibration, maintenance and, if necessary, repair with just one visit

- Fixed prices with a clear breakdown of costs

- Preventive maintenance helps you avoid expensive faults and ensures a high level of quality that lasts

The maintenance contract includes:

- Travelling time and expenses for our technician

- Maintenance and calibration work

- Small items required for carrying out the specified maintenance work

- Calibration with a corresponding maintenance and test report, allowing the results to be used to demonstrate compliance with national standards

We offer the super six-sided pre-squaring on mold steel plate preparation, producing a milled, squared and chamfered plate ready for production without costly and destructive grinding.2. After sale service, we will help you at once when there is a problem. besides, we will check machine regularly.3. Machines come wired for USA electricity or your local electricity.4. We supply expert installation and training.Don't worry and trust us, we will all here serve for you