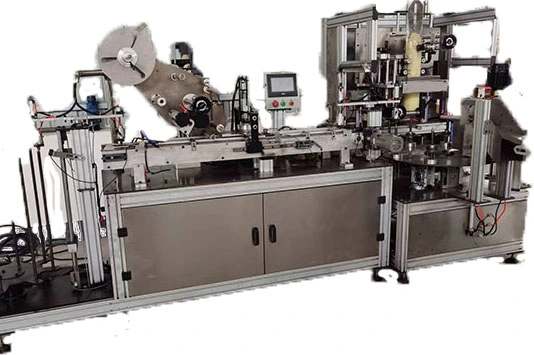

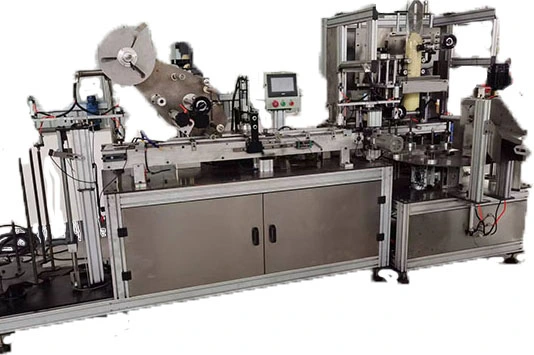

Full Automatic Flap Disc Labelling and Packaging Machine

Flap Disc Labeling & Packaging Machine This fully automatic, high-efficiency machine labeling for flap discs.A fully aut;

Basic Info

| Model NO. | KWTB-02 /KWSF-02 |

| Production Capacity | 300/Per Year |

Product Description

Flap Disc Labeling & Packaging Machine

This fully automatic, high-efficiency machine labeling for flap discs.A fully automatic labeling machine is designed for coated abrasive disc products. The machine can auto-pick products, position detecting, labeling, auto put them in order and auto-pack. With a high degree of automation, high efficiency, and stable quality. The cost of raw materials is low, maximizing profits. It can be packed 16000 pieces per 8 hours.

Equipment performance and characteristics

1. Humanized mechanical structure design, easy to operate, a high degree of automation, set labeling and packing as one, a single operator can easily complete the operation.2. Use ordinary paper labels, and ordinary liquid glue, which greatly reduces the cost to the users and maximizes the profits of the users.3. Selection of European standard industrial materials, by professional CNC machining overall fine milling, fine grinding, and molding at once, stable and durable.4. The drive parts adopt an internationally famous brand of electric components, high-speed servo motor, reducer, and industrial level control system, which can respond to micro displacement and positioning accuracy. Perfect function, high efficiency, and stable performance.5. During the labeling system, use the internationally famous brand photoelectric switch to detect the product, and auto pass no-product workstation, stable and accurate.6. Uses the modular assembly, the adjustment and maintenance of the machine are convenient.

Technical parameters:

| Model | Labeling machine KWTB-02 | Packing machine KWSF-02 | |

| Product size | 75mm--180mm | ||

| Power supply | Pneumatic, Electric | ||

| Operator | 1 | ||

| Voltage | 380V | ||

| Production capacity | 9600P/8H | 816P/8H(10pcs as one shaft) | |

| Installed power | 3KW | 12KW | |

| Main machine size | 1500*1200*1500 | 2580*1400*1350 | |

| Photoelectric sensor | Autonics | Cylinder | Airtac |

| Magnetic switch | Airtac | Control panel | Weinview |

| Bearing | NSK | PLC | Delta |

| Motor | Panasonic | Pneumatic component | SMC |

. Save labor cost

. Improve production efficiency

. Good quality products

. Stable production

. Humanization design

To ensure the integrity and safety of product packaging, main products are packed in plastic film or export plywood boxes, and auxiliary products are packed in thick cartons.Do you provide customized services?We can design the machine according to your requirements (material, power, size, etc.). We will also provide you with expert guidance at the same time, based on our many years of experience in the industry.How will my machine be installed once it arrives? How much does it cost?We'll dispatch an engineer to your facility to assess the situation, install the machine and train your staff on how to operate it. The customer pays for round-trip airfare, accommodation, and USD100/day/person.Are you a manufacturing or a trading company?We are a factory, and we offer factory direct prices with excellent quality and worry-free service. Please come and see us here!What is your guarantee or warranty if we buy your machine?We offer you a 1-5 years warranty on our high-quality machines and lifetime technical support.

You may also like

Send inquiry

Send now