Chinese Manufacturer Yihong High Quality Full Automatic Flap Disc Machine for Abrasive Tooling Flap Disc Making

Basic Info

| Model NO. | full automatic flap disc machine |

| Disc Type | Fiberglass/Plastic |

| Glue-Spread | 4-30g |

| Production Speed | 6000-8000 PCS/10h |

| Operator | One |

| Glue Pump Weight | 280kg |

| Motor | Import Panasinco Servo Motor |

| Glue System | Air Tac Cylinder SMC Counter Control Valve |

| Host Engine | Servo Motors 5kw Heating 2kw |

| Dimensions of Main Machine | 1300mm*1400mm*1500mm |

| After-Sales Service Provided | Video Technical Support |

| After Warranty Service | Video Technical Support |

| Machinery Test Report | Provided |

| Core Components | PLC, Engine, Motor |

| Applicable Industries | Manufacturing Plant, Other |

| Transport Package | Strong Wooden Case |

| Specification | backing pad: 75-180mm |

| Trademark | yihong |

| Origin | Henan, China |

| Production Capacity | 10 Sets/Month |

Packaging & Delivery

Package size per unit product 410.00cm * 1900.00cm * 200.00cm Gross weight per unit product 30.000kgProduct Description

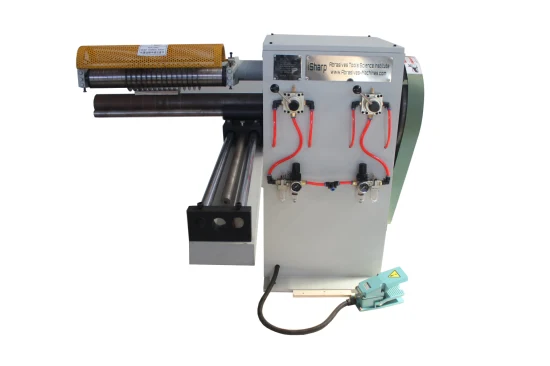

Full automatic flap disc forming machine can realize automatic put the backing pad,backing pad detection,quantitative glue,row sheet and cutting abrasive belt,automatic flap disc forming,automatic unloading product process automation production.

High degree of automation,single can complete the whole operation,for you to save labor costs.

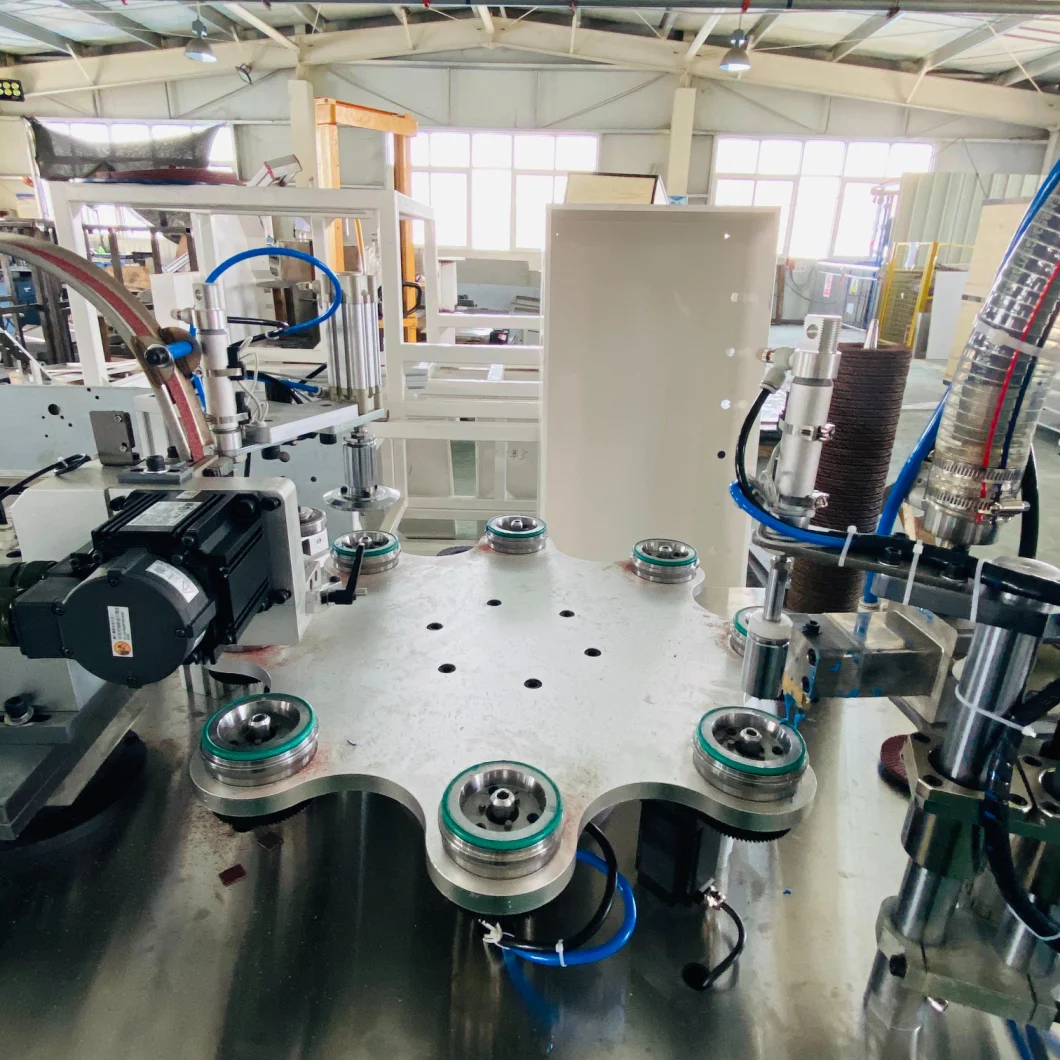

Using more station turntable,the station is stable and accurate positioning.

Glue system adopts water circulation constant temperature control system,to provide the need temperature of glue.Simple and efficiency.

The products in the production adopts import photoelectric sensor switch,accurate detection save times.

The head can adjustable of row sheet angle,according the parameters of dividing rule can help the head accurate adjustable and translation.Guide rail inside the head dust proof and ash, Provide the service life of the guide rail.

High production efficiency,the machine every hours can produce 800-900 pcs.

High utilization rate of production materials,one component adhesive and abrasive belt can be freely set,services for small and medium-sized enterprises.

Very low scrap rate,in after of machine adjustment,close to zero percent of the scrap, don't worry you machine production.

Technical Specification

Full automatic flap disc machineTechnical data:

Electric Plant Characteristics:

Installed Power:4KW + 1.5KW ( Dust)+2.5kw(Heating)

Voltage: 380V( indicated on the electric board)

Auxiliary Voltage: 24V

Operation: Electromechanical

Production Performances:

Disc Size: Diameters: 100, 115, 125, 150, 180mm

Flap Size: Width: 20-40mm, Length: 15-28mm

Production efficiency: 12pcs flap discs (single-flap 115*22*72 flaps disc) per minute

Full automatic flap disc machine Data:

Stations of Rotary Plate: 12

Electrical Power Supply: 380 V/50-60HZ

Air Consumption: 100 litres/min

Glue Pump: 280kg / 30kg

Flap disc type: T27, T29

Flap disc surface: Conventional Disc, Double Same Cloth Disc, Double Different Cloth Disc, Long & short cloth Disc.

Backing: Fibreglass, Plastic, Nylon, Metal

Backing Disc Size: 70~170 m

Flap Disc Size: 100~180mm

Flap Size (W x L): 20~40 x 15~25mm

Max. Backing Capacity : 1200 pcs

Max. Disc Capacity: 50pcs

| Stations of Rotary Plate | 12 |

| Glue Pump | 280kgs / 30kgs |

| Electrical Power Supply | 380V/50-60Hz |

| Air Consumption: | 100 litres/min |

| Product Data | |

| Flap Disc Type | T27/T29 |

| Flap Disc Surface | Conventional Disc, Double Same Cloth Disc, Flexible Disc |

| Flap Disc Backing | Fibreglass, Plastic, Nylon, Metal |

| Backing Size | 75-170mm |

| Flap Disc Size | 100-180mm |

| Flap Size | 20~40x5~25mm |

| Glue Consumption per Flap Disc | |

| 100 mm / 4" Flap Disc | 5~8 g |

| 115 mm /4.5" Flap Disc | 8~12 g |

| 125 mm / 5" Flap Disc | 12~16 g |

| 180 mm / 7" Flap Disc | 20~30 g |

| Flaps on Each Flap Disc | 45~150pcs |

| Dimension | 2600x 19000 x2000(H)mm without glue pump |

| Dimension | 4100x19000x2000(H)mm with glue pump |

| Weight: | 1060kg without glue pump |

| Weight: | 1300kg with glue pump |

1.Good synchronous consumption for polishing stainless steel

2.China manufacture Long-term experience and well-management for quality

3.Durable

4.Aggressive stock removal

5.Good heat dissipation and pure workpieces

6.High performance and high safety

7.Advanced production process for steady work performance

8.High quality and low price

9.High efficiency, Top flexible grinding

10.Suitable grinding

Jia County Yihong Abrasives is a specialized manufacturer of abrasive products and abrasive machine. Our company products mainly include flap disc, flap wheel , flower flap disc, mounted wheel, wire flap wheel, abrasive cloth and glass fiber backing plate. With many years technological innovation and honing, our company has successfully developed and built flap wheel,flap disc production line and fiberglass backing production line, realizing the large-scale production of abrasive cloth polishing abrasives.

Our company sales network has been initially established throughout the country and has been successfully exported to Europe, America, South east Asia and other regions. On the basis of quality assurance, the company has won wide recognition from industry colleagues and customers with its good reputation and excellent service.

Q1 : What's your advantages?A1 : We are abrasives manufacturer,also can customize special types abrasive items for customers' requireQ2 : What's the quality of your products?A2 : We have a strict quality controlling system which promises our goods are always with the best quality.Q3 : Do you have after-sales services?A3 : Yes, We have complete after-sales services, if you encounter any quality problems with our products,please contact us in time.Q4 : Can I free get the sample?A4 : Sure,we can offer free samples to you and you only need to pay for the express cost.Q5 : How can order products without any acknowledge of import?A5 : We can arrange shipping or air express for you.Delivery goods to your nearest port or provide you Door to Door service.