Abrasive Grinding Flap Wheel Cloth / Abrasives Disc Making Non Woven Machine/ Nonwoven Fleece Wheel Finishing Flap Brush Processing Equipment Whole Line Machine

The scouring pad includes industrial scouring pad, civilian scouring pad, sand scouring pad, sand-free scouring pad and ;

Basic Info

| Model NO. | HR-2 |

| Customized | Customized |

| Condition | New |

| After-sales Service | 1 Year |

| Item | Cleaning Pad Produc Making Machine Whole Productio |

| Voltage | 380V/50Hz 3phase Can Be Customized |

| Machine Painting Color | Be Made According to Your Need |

| Price | Lowest Reasonable Offers in The Market |

| Delivery Time | 25-30 Days |

| After-Sales Service Provided | Engineers Available to Service Machinery Overseas |

| Working Experience | 32 Years′ Experience |

| Heating Temperature | 120-180 Degree |

| Equipment Size | 2500mm*5900mm Can Be Customized |

| Transport Package | Standard Package, Be Made According Cutomer Need |

| Specification | Width 2000-7200 mm |

| Trademark | HUARUI |

| Origin | Qingdao |

| HS Code | 84451190 |

| Production Capacity | 100 Sets / Month |

Product Description

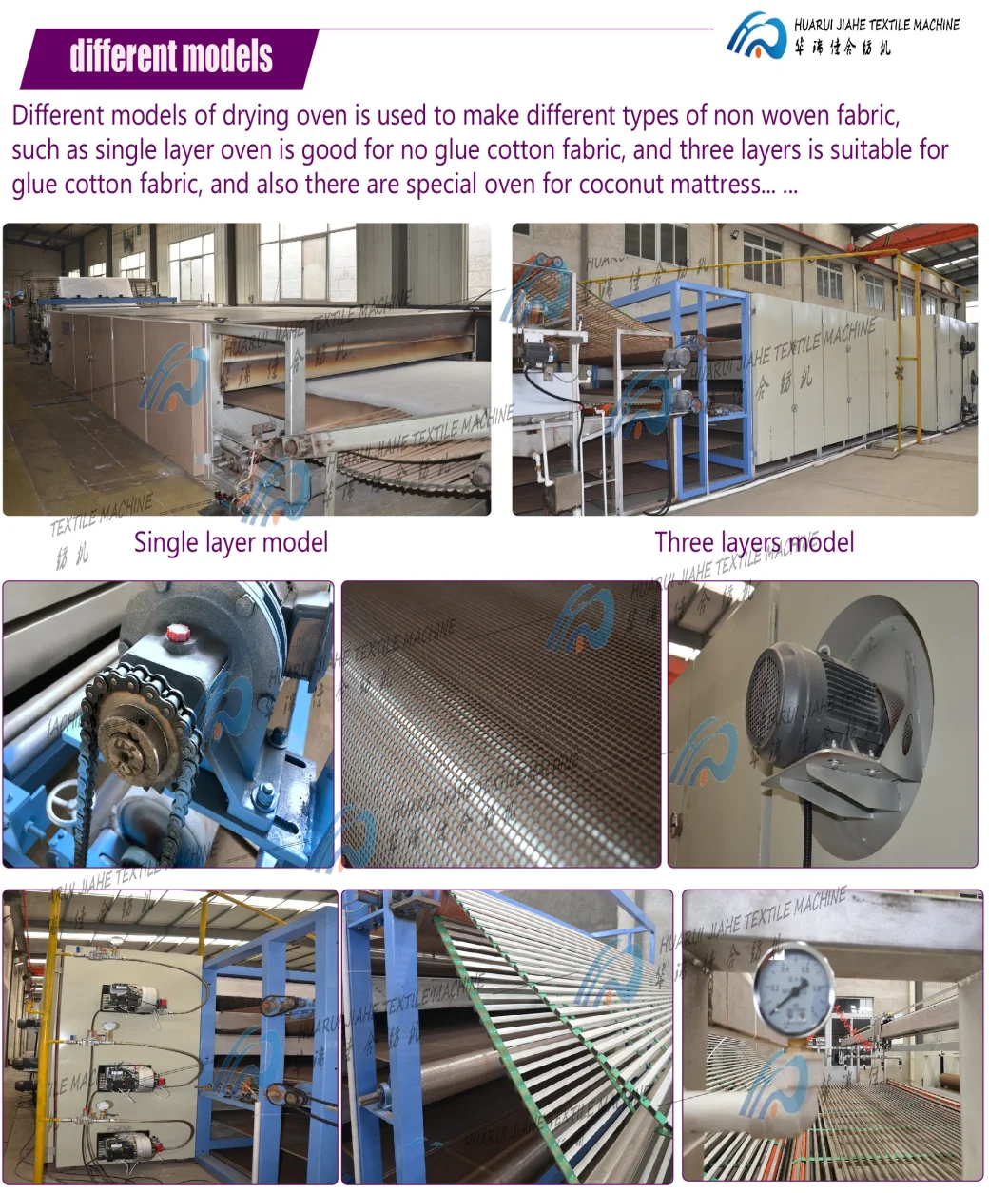

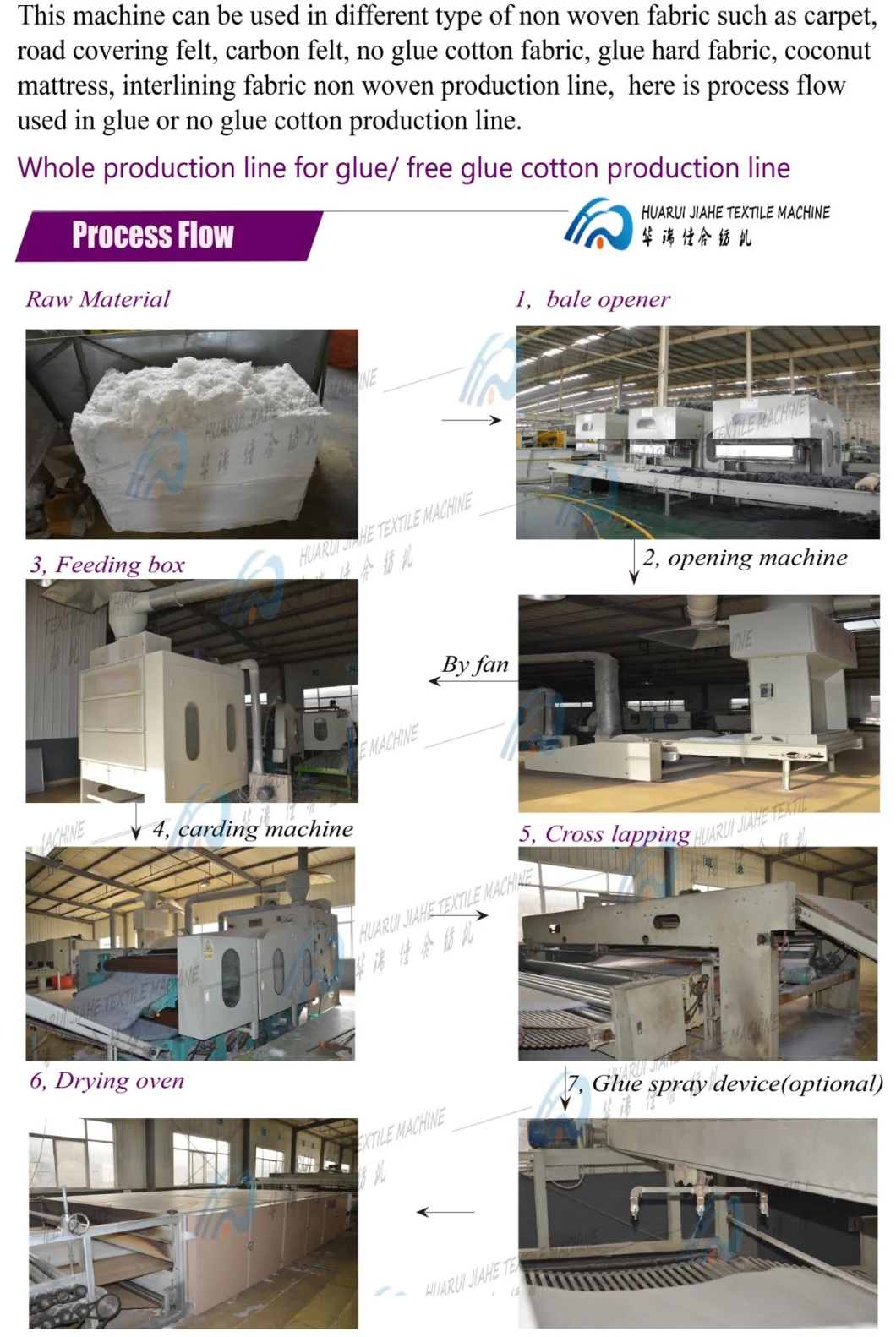

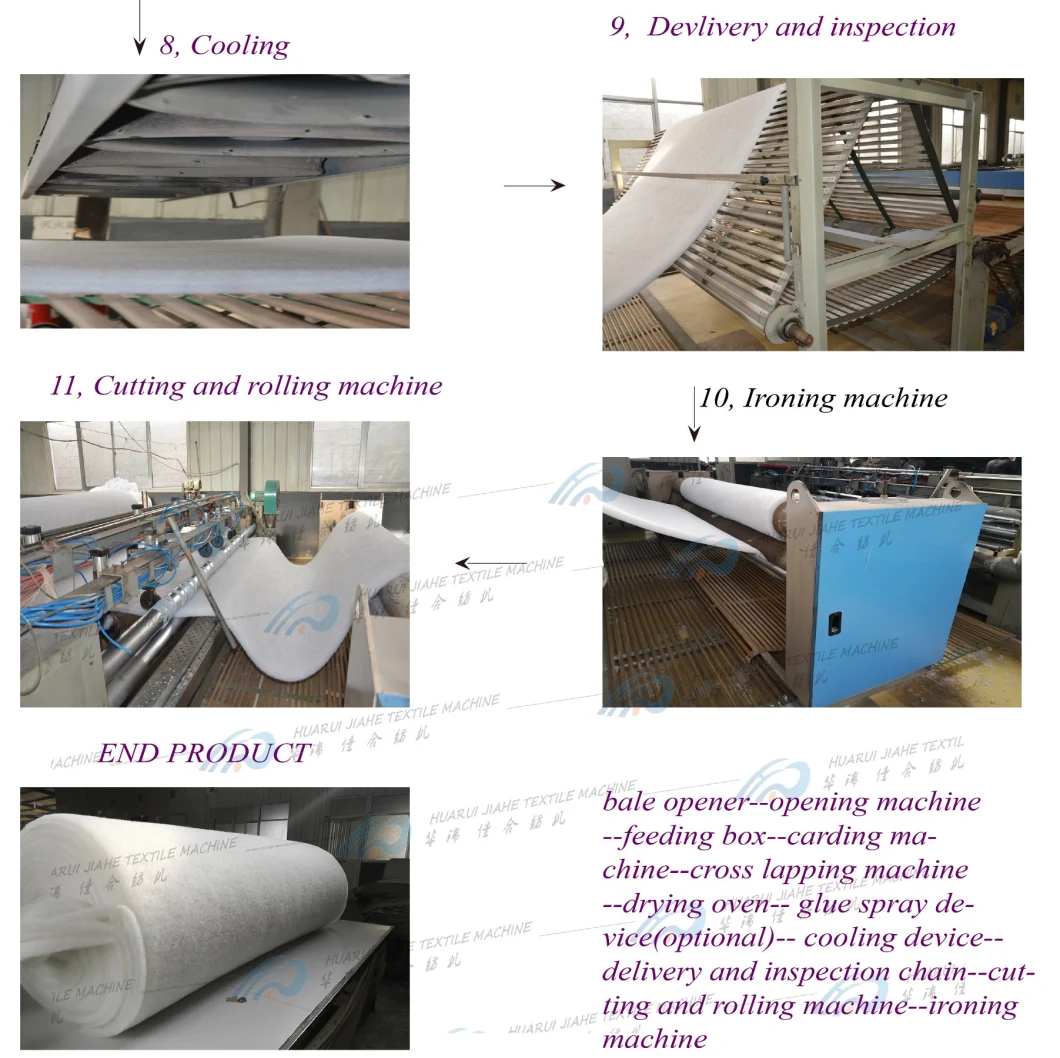

The scouring pad includes industrial scouring pad, civilian scouring pad, sand scouring pad, sand-free scouring pad and other products. The products are widely used in decoration, metal polishing and daily washing, and are widely used in the market. Usually this fabric is mainly made by single layer or three layer oven, and here is whole production line show which is similar with glue cotton production line.

Usage of oven:

This machine is suitable for heating. The heating method uses up and down heating, dual use of coal and electricity. Stainless steel chain plate structure is inside of the machine. Oven chain, curtain rods are clamped into the net. Teflon wrapped into the net, the upper layer can be electrically lifted to ensure that the product surface is smooth and flat.Machine structure: There are direct -type oven, double layer oven and three-layer oven to choose.Heating temperature: 120-180°CEquipment size: 2500mm*5900mm can be customized

Technical Data:

| Voltage | 380V,50HZ,3Phase |

| Working width | 3100mm,3800mm |

| Product width | 2500mm,3200mm |

| Oven temperature | 0-250ºC |

| Weight range | 60-300g/m2 |

| Box length | 8000mm/10000mm/12000mm |

| Specification | 60-300g/m2 |

| Yield | 100-260kg/h(custom made) |

Features:

1. Uses two layers of Teflon mesh to clamp into the cotton2. its Thickness is controlled by lifting system3 drying room heating method: Thermal conductive oil4. Air fan is controlled by two 15kw motors to control its air volume and distribute air evenly5 insulation board is made of cold-rolled plate, the middle insulation body using aluminum silicate material

You may also like

Send inquiry

Send now