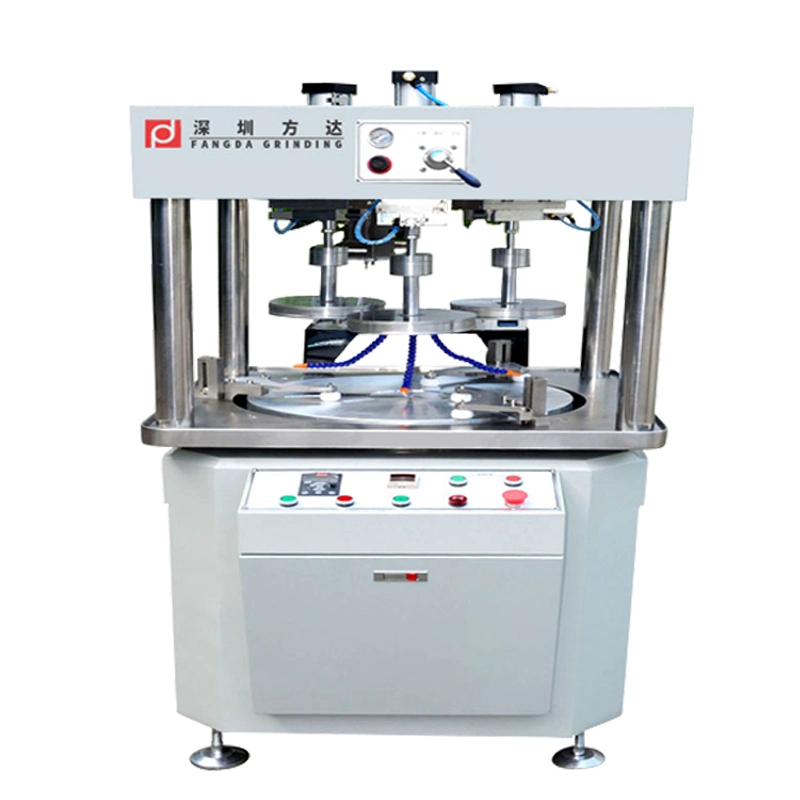

a 610 Plane Grinding and Polishing Machine with an Electroplating Dressing Wheel

Why Ponda? Ponda has profound experience of lapping, polishing and thinning. We heretofore supplied more than 60, 000 la;

Basic Info

| Model NO. | 610 |

| Class | Double Plate |

| Process Station | 3-5 |

| Pressure Source | Pneumatic |

| Plate Material | Metal and Non-Metal |

| Abrasive | Lapping Slurry |

| Transport Package | Wood Crate |

| Trademark | PONDA |

| Origin | China |

| Production Capacity | 500 Unit/Year |

Product Description

Why Ponda?Ponda has profound experience of lapping, polishing and thinning. We heretofore supplied more than 60, 000 lapping process solutions and appliances over the industries of machinery, electronic, aerospace, aviation, automotive, atomic energy, optics; the substances of metal, wafer substrate, ceramics, glass, industrial sapphire, plastics, and any other composites.

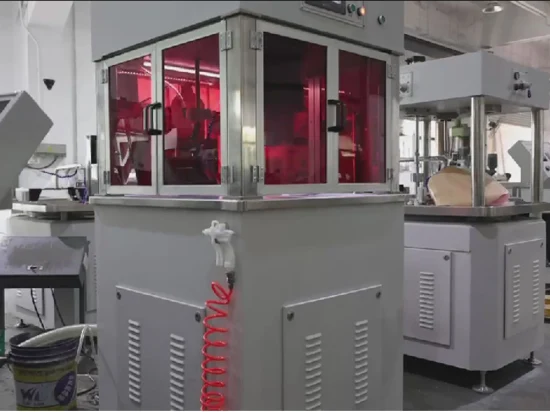

Products Show

Working principle:

1. The equipment is changed to precision grinding and polishing equipment. The grinding and polishing materials are placed on the grinding disc, which rotates against the clock, the correction wheel drives the workpiece to rotate, the workpiece is pressed by gravity pressure, and the workpiece and the grinding disc make relative running friction to achieve the purpose of grinding and polishing.2. The dressing mechanism of the grinding disc adopts the hydraulic suspension guide rail to move back and forth, and the diamond trimming knife trims the grinding surface of the grinding disc precisely to obtain the ideal plane effect.Special points:1. Usually, the way of grinding disc shaving is to use electroplating dressing wheel to shave, which is not ideal. After shaving by dressing mechanism, the flatness can reach ±0.002mm2. The workpiece pressure of the equipment adopts the cylinder pressure, the pressure can be adjusted;3. The equipment adopts PLC program control system, touch screen operation panel, grinding disk speed and timing can be directly input on the touch screen.

APPLICATION

| Process | Industry by Substance | Industry by Applicability | |

| Double Plate Lapping & Polishing | Metal And AlloyCeramicOxideCarbideGlassPlasticNature Stone | Sealing | valve and sealing ring(liquid, oil, gas) |

| Semiconductor | LED substrate(Al2O3, Si, SiC)wafer substrate(Si, SiC, Ge, Ge-Si, GaN, GaAs, GaAsAl, GaAsP, InSb, ZnO, AlN) | ||

| Plastic | PE, E/VAC, SBS, SBR, NBR, SR, BR, PR | ||

| Optics(flat) | optical lens, optical reflector, scintillator cube, holographic glass, HUD glass, screen glass | ||

| Gemstone | jade, sapphire, agate, etc. | ||

| Others | graphite block, gauge block, micrometer gauge, diamond, friction plate, knife, bearing, metal components, and any other precise hardware. | ||

| *NOTE: lapping can only remove slight thickness of workpiece. If need ultra thinning(≤100μm), thinner machine are needed. | |||

SPECIFICATION

| Standard Specification | |||||

| Machine Model | FD6B | FD9B | FD13-6B | ||

| Lower Plate Diameter | Φ386 mm / 15 inches | Φ640 mm / 25 inches | Φ973 mm / 38 inches | ||

| Upper Plate Diameter | Φ386 mm / 15 inches | Φ640 mm / 25 inches | Φ973 mm / 38 inches | ||

| Star Wheel Parameter | DP 12, Z=66, A=20° | DP 12, Z=108, A=20° | DP 19.3, Z=152, A=20° | ||

| Conditioning Ring Parameter | DP 12, Z=66, A=20° | DP 12, Z=108, A=20° | DP 19.3, Z=152, A=20° | ||

| Max. Workpiece Diameter | Φ120 mm | Φ180 mm | Φ290 mm | ||

| Process Thickness | 0.2mm≤N≤20mm | 0.2mm≤N≤25mm | 0.2mm≤N≤30mm | ||

| Number of Station | 3≤N≤5 | 3≤N≤5 | 3≤N≤5 | ||

| Plate Rotate Speed | 0-60 rpm | 0-60 rpm | 0-50 rpm | ||

| Total Weight | 600 kg | 2000 kg | 3200 kg | ||

| Total Floor Space | 700×950 mm | 1350x960 mm | 1700×1380 mm | ||

| Built-In Optional Kits | |||||

| Grade | Standard | Advanced | |||

| Slurry Supply System | - | Integrated with PLC | |||

| Facing and Grooving System | - | Integrated with PLC | |||

| Machine Enclosure | - | Framed by Metal Plate | |||

| *NOTE: the optional kits based on the production requirements, making samples can confirm if they are necessary. | |||||

SAMPLE DEMONSTRATION (DOUBLE PLATE)

About the Company

Factory front desk

Ponda is a high-tech enterprise specializing in all kinds of high precision grinding equipment, polishing equipment and itssupporting products and consumable materials

Patent

FAQs

Q1: Which machine is most applicable for my product?

A: It usually depends on 5 requirements and parameters of your product: flatness, roughness, thickness, dimension, productivity:1. If better flatness and roughness were required, you might need both lapping and polishing machine.2. If to thin the product in a big margin, such as 500μm, you might need a thinner machine for extra.3. If the productivity were excessive, you might need larger machine or to expand production line.Additionally, we can confirm the production line as we make samples for you.Q2: Does Ponda charge for making samples?

A: No, it's free to make samples.

Q3: Is Ponda trader or manufacturer?

A: We are manufacturer, certified National High-Tech Enterprise.Q4: How long does it take machine to deliver?

A: Approximately 15 days to deliver. If the machine are out of stock, we need 15 days more to manufacture.Q5: Does Ponda provide oversea setup and after-sale service?

A: Yes, we provide oversea service and online tutorial.Q6: How many type of machine does Ponda manufacture?

A: We have 21 major series of machines, 5 different types run in different principles, more than 15 types of plates, 100 types of slurries.

You may also like

Send inquiry

Send now