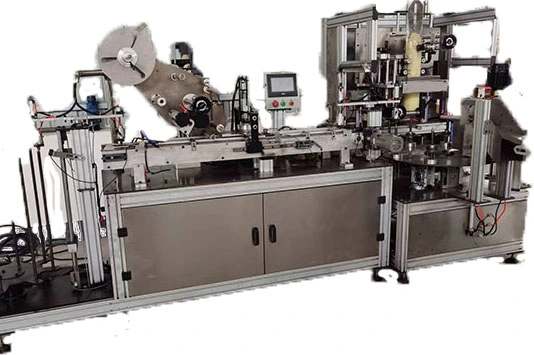

Grinding Wheels Hole Plastering Machine Hole Coating Machine

Basic Info

| Model NO. | B-CHM-65x120 |

| Products Range | D20-65mm, T120mm |

| Spindle Speed | 70-3500rpm Stepless Speed Adjustment |

| Power | 4kw |

| Size | 1300X650X1820mm (Lxwxh) |

| Weight | 900kgs |

| Related Machine | Universal Grinding Wheel Dressing Machine |

| Transport Package | Export Standard Wooden Case |

| Specification | B-SIM-400x150 |

| Trademark | iSharp |

| Origin | China |

| HS Code | 84748020 |

| Production Capacity | 500 Sets Per Year |

Product Description

Grinding wheels hole plastering machine hole coating machine

Product Description

The grinding wheels hole plastering machine hole coating machine characterizes:

1. Putty layer not easy to break away from the hole

2. The putty can be mixed with different pigment to make the grinding wheels hole more beautiful

3. No need heating after applying the putty

4. Hydraulic automatic unloading, high efficiency

5. High processing precision, high efficiency and easy maintenance

6. Mandrel positioning with linear bearing guide, ensuing the verticality requirement when changing the mandrel

7. PLC

| Model | B-CHM-65x120 | B-CHM-305x200 |

| Working range | D20-65mm, T120mm | D65-305mm, T200mm |

| Size(LxWxH) | 1300x650x1820mm | 1300x650x1820mm |

| Weight | 900kgs | 900kgs |

Related Machinery

The 8000-9500pcs/8hs cutting discs making machine grinding wheel production line for sale has features as below:--Cutting discs and grinding wheels can be made in one machine--100-125mm diameter can be made in one machine, 150-230 in another, 300-400 in one machine--Working stations adjustable as customers' request--Functions adjustable as your specific cutting discs and grinding wheels request--Automatic units optional for instance, automatic feeding, automatic put net, automatic put fiberglass bet, steel ring and label device, automatic pile up unit and so on --Semi automatic machine can be updated to fully automatic--Full production line can be provided besides the main press for cutting discs and grinding wheels making, you can also get the hydraulic mixer, oven, packing machine and so on.--Besides machines for cutting discs production line, you could also get raw materials + formulas + installation service + production guidance + after-sales service

Packaging & Shipping

For the packing, iSharp Abrasives will pack the grinding wheels hole plastering machine hole coating machine in export standard wooden case which is based on steel frame consideration of the machine weight. We will also fix the machines on the wooden case bottom plate with screws and wrap with plastic film to do the best to make your skiving machine for abrasive belt converting making safe in the shipping period.For the shipping, sea shipping, air shipping and railway shipping are all supported. iSharp Abrasives will use its optimized operation process to save your waiting time not only in production step, but also the shipping step. That's also the special advantage of iSharp Abrasives.

Our Advantages

--Good quality which has been approved by customers in Europe, the US, Mexico, Russia, Ukraine, Singapore and so on.

--Excellent service to understand what you want, meet your request or sometimes offer better ideas. :):)

--Responsible after-sales service to help you deal with any problem in machine operation and so on.

--Long term view of co-operation, value-propositioned supplier. With this belief, you will find a trustable supplier.

--Comprehnesive supplier, besides the grinding wheels hole plastering machine hole coating machine , we also have other series coated abrasives machines and bonded abrasives machines for your choice!

After Sales Service

Any problem will be answered in 24hours to co-operate with you to solve the problem, we are always together with you. Overseas installation and adjustment will be provided if you need and the whole preriod will be only one week. Relative cost will be negotiated by both parties.

Company Profile

ISHARP ABRASIVES TOOLS SCIENCE INSTITUTE is a leading grinding solutions provider in China. Experienced abrasive engineers constitute a research team. Our joint factories develop and manufacture bonded abrasives, coated abrasives, non-woven abrasives and abrasive machines. Adhering to the concept of"Green, Efficiency, Precision", we design, develop and produce suitable abrasive products, machines and offer technology support. iSharp helps the users to improve grinding efficiency and quality, save grinding cost, improve their competitiveness and achieve their value. iSharp's products include resin bonded cutting disc making machines, ceramic bonded grinding wheel making and dressing machines, coated abrasive conversion machine, flap disc production line, mounted flap wheel machines, flanged flap wheel making machines, curing ovens andrelated materials and accessories.

Expect you enjoy iSharp's quality products and outstanding services!

Welcome to contact us for more details of the grinding wheels hole plastering machine hole coating machine!iSharp Abrasives Tools Science InstituteA2507, KaiXuanMen, TongBai S. Rd. 238, ZhengZhou, HeNan, 450006, China